Lug Analysis Validation

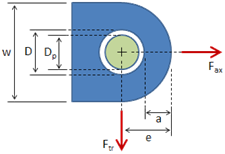

In Section 9.6 of the Air Force Stress Analysis Manual, an example is provided for an axially loaded lug. The male lug strength, female lug strength, and double shear joint strength are calculated. This validation case follows the Air Force example to ensure consistent results between the Air Force Manual and MechaniCalc's Lug Analysis calculator.

Joint Strength

The relevant inputs, per the input table, are specified below:

Pin Geometry:

| DP | = | 0.75 in | pin diameter |

Joint Geometry:

| g | = | 0.10 in | gap |

Pin Material Properties: 4130 Steel

| Sty | = | 103,000 psi | tensile yield strength |

| Stu | = | 125,000 psi | tensile ultimate strength |

| Ssu | = | 82,000 psi | shear ultimate strength |

| E | = | 29.0 x 106 psi | elastic modulus |

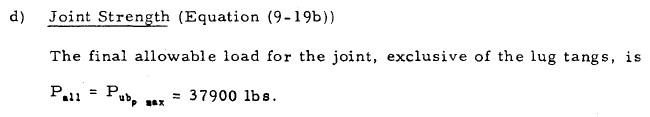

Comparison Summary

A summary of the joint strength results calculated in the Air Force Manual versus those calculated in MechaniCalc's Lug Analysis calculator is provided below. It can be seen that the results are essentially equivalent.

| Air Force Manual | MechaniCalc Lug Calculator | |

|---|---|---|

| Nominal Joint Strength | 44,000 lbf | 44,010 lbf |

| Pin Ultimate Shear Load | 72,400 lbf | 63,728 lbf |

| Pin Ultimate Bending Load | 30,100 lbf | 30,052 lbf |

| Pin Ultimate Bending Load, Balanced | 37,900 lbf | 37,801 lbf |

| Bearing Width, Female Lug, \(b_1\) | 0.331 in | 0.332 in |

| Full Bearing Width, Male Lug, \(2 b_2\) | 0.646 in | 0.644 in |

| Overall Ultimate Load | 37,900 lbf | 37,801 lbf |

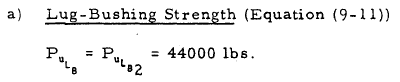

Lug-Bushing Strength (Nominal Joint Strength)

The nominal lug-bushing strength as determined in the Air Force Manual is:

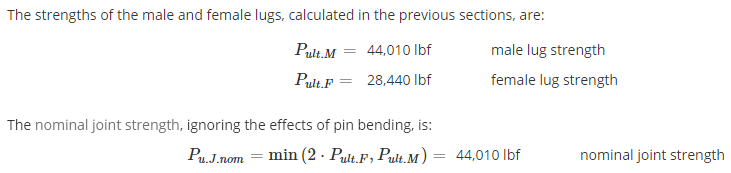

The results from the Lug Analysis calculator are shown below. These results are equivalent to those from the Air Force Manual:

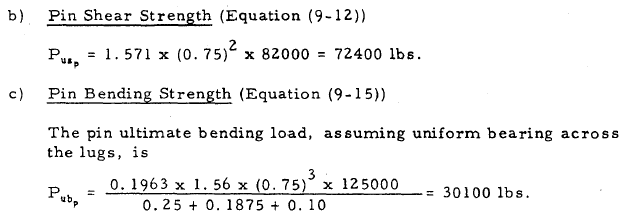

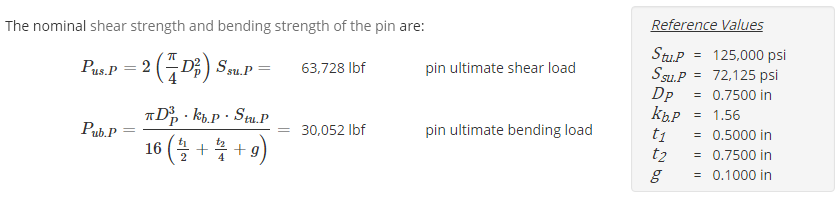

Nominal Pin Strength

The nominal pin strength as determined in the Air Force Manual is:

The results from the Lug Analysis calculator are shown below. The calculated bending strength is equivalent to that calculated in the Air Force Manual. However, the calculated shear strength is lower than that from the Air Force Manual. The reason is the value of shear ultimate strength for the pin, \(S_{su.P}\). The Air Force Manual specified a shear ultimate strength of 82,000 lbf. However, MechaniCalc makes the assumption of \( S_{su} = 0.577 \cdot S_{tu} \), which gives a shear ultimate strength of 72,125 psi for the pin material.

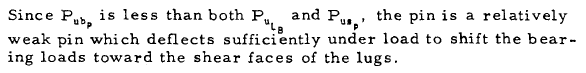

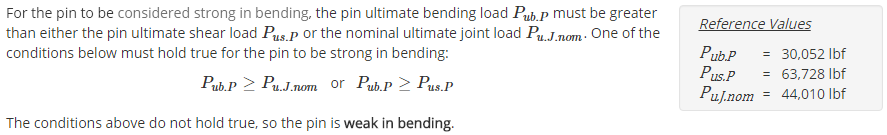

Pin Strong or Weak in Bending?

The Air Force Manual determines the pin to be weak in bending:

The Lug Analysis calculator makes the same conclusion:

Weak Pin - "Balanced Design"

The pin bending strength in the balanced design calculated by the Air Force Manual is:

The effective bearing widths in the balanced design calculated by the Air Force Manual are:

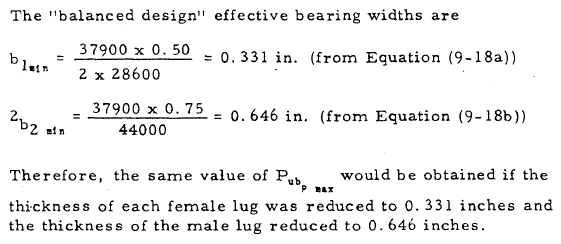

The results from the Lug Analysis calculator are shown below. These results match those from the Air Force Manual:

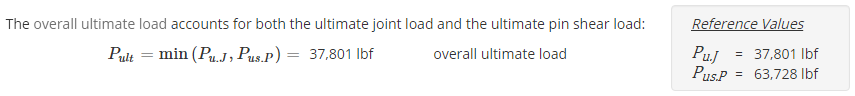

Overall Ultimate Load

The ultimate load as calculated in the Air Force Manual is:

The results from the Lug Analysis calculator are shown below. These results are equivalent to those from the Air Force Manual: